Note from Jane: Today’s post is excerpted from the book Cover to Cover by Andrew Watson, a comprehensive guide to self-publishing a print book or ebook, mainly for those in Australia. However, the book printing information below is applicable to any author who wants to invest in a print run for their book.

Keep in mind that, due to the pandemic (and other factors), the market right now is very tight for paper and printing, with long lead times and increased pricing. Plan far in advance if you have a specific release date in mind.

Choosing the right materials for your book, and the right printer, is more important than you might think. They will not only affect its physical appearance but also influence a potential customer’s perception of value for money. You’ll also need to know exactly what to ask for when requesting and receiving quotes from a printer whether near you or overseas.

Everything below should be regarded as general guidance only. There will, inevitably, be variations depending on what is available at the time and the technical preferences of your nominated printer. When in doubt, always get a sample.

Depending on where your printer is based, they may express a paper’s weight in pounds per ream (#), grams per square meter (gsm), or points (pt). In this article, we’ve provided US and rest-of-world equivalents.

Note also that papers manufactured for different purposes utilize different systems of measurement. For example, a 100# cover stock is much heavier and more rigid than a 100# text stock.

Text paper

Generally, paper used for the text pages in a typical book will be either coated or uncoated. A coated paper has had a fine layer of china clay or a similar synthetic substance applied to make a smooth, sealed surface. Uncoated papers are, for the most part, everything else.

Gloss, art, satin, semi-matte and matte papers are all coated stocks. The principle is the same for all of them—ink sits on the surface of the paper rather than being allowed to soak in or spread. This allows for precise color registration and enables high quality image reproduction. For this reason coated paper is nearly always white. Indeed, many books that appear to use cream-coated stock are actually white with the non-illustrated areas printed in a light cream color from edge to edge.

The process of applying the coating on both sides tends to flatten the fibers so, although coated papers might have exactly the same weight as uncoated ones, they are noticeably thinner. This, in turn, means a book with coated paper will be considerably slimmer than one with the same page extent using uncoated paper and this may affect the customer’s perception of value for money. Publishers often try to compensate by using heavier gloss paper (from, say, a standard 90 or 100 gsm/60# or 70# stock up to 120 gsm/80# or greater) but this can make the book much heavier and is something to consider if large quantities are being sent by ordinary mail.

Uncoated papers, apart from being, you know, uncoated, come in an extraordinary range of weights and thicknesses and shades of white and cream. They are non-reflective and eminently suitable for a wide variety of uses in book production. They can be as thin as tissue for Bibles and large reference books (literally known as bible paper), all the way up to almost card-like quality for children’s picture books.

Generally, weight corresponds to thickness—the heavier the paper, the fatter it is, but some lightweight stocks leave the fibers deliberately fluffed up to make the paper seem thicker. This ‘bulky’ paper is frequently used in mass market novels to give the appearance of greater value for money.

Weights of text stock can vary between 70 gsm and 120 gsm/50# and 80#. A consideration here is the potential for show-through which occurs when printed matter on one side of a page is clearly visible on the reverse side. This is less likely to happen with coated stock but it can be problematic with lower weights of uncoated paper. If you are unsure about choosing a paper stock for this reason you should ask your printer for recommendations and obtain samples of pages printed on different weights of paper.

All this is, of course, assuming that your nominated printer will actually allow you to choose your own paper. Many do not, primarily because they purchase a small range of paper types in bulk which they then allocate to specific formats of book. Digital printers, in particular, will only use one

or two types of paper for black and white production (eg. 80 gsm or 90 gsm/55# or 60#) and will only increase the weight if the book contains ink-heavy color pages. Choice of paper stock may also be determined by whether your printer uses a sheet-fed machine (eg. single sheets of paper) or a large web-offset machine fed by large rolls of paper.

Paperback cover

Ideally, card for paperback (sometimes called limp or softback) covers should be between 240 gsm and 270 gsm/12 pt. and 15 pt. Outside this range the book can become either too floppy or stiff and awkward to open. Again, it is advisable to obtain a sample of the material to be absolutely sure it is what you want.

Hardback cover

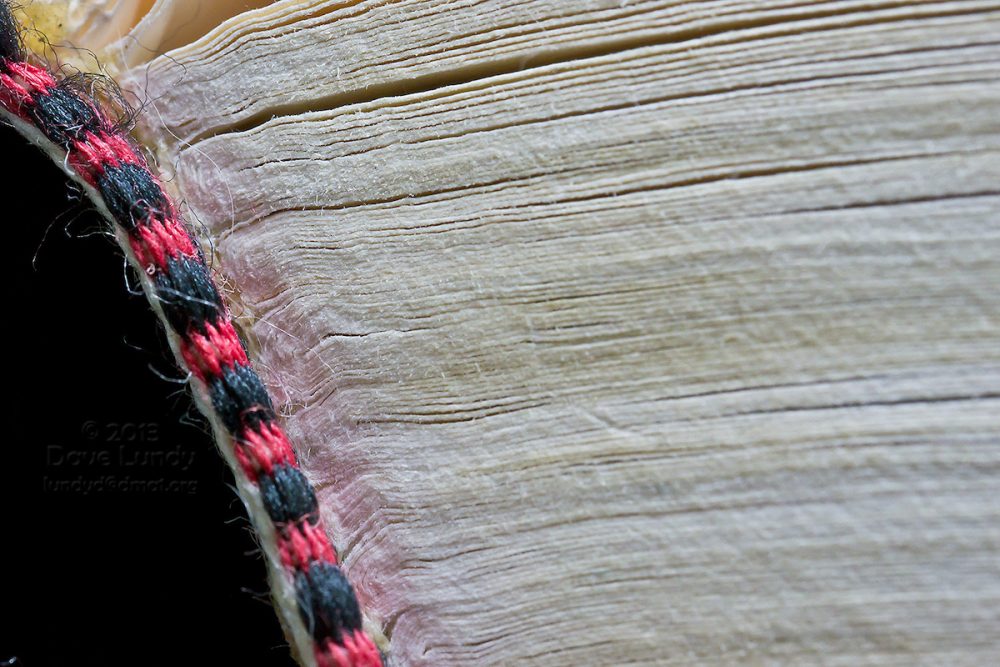

A hardback (or cased) cover has four main components: the board itself, endpapers which help to attach the board to the block of pages, the board covering, and the dustjacket. In the past the board covering would have been thin leather or a textured material but is it much more common now for it to be a printed paper covering which replicates the dustjacket or perhaps eliminates the need for a jacket altogether.

Board: Normally formed from grey card, kraft board or mill board. The most suitable weight is around 40 oz (1800 gsm/100 pt.) but can range between 16 oz (1000 gsm/55 pt.) and 48 oz (2200 gsm/120 pt.). Boards may warp if they contain too much moisture when the endpapers are attached and then dry out. This frequently happens when the grain of the endpaper runs in the same direction as the grain in the board instead of being applied at a right angle.

Endpapers: These are usually around 110 gsm/75# although the thickness may depend on the book’s weight and format size. They help to attach the book block to the board and so the material used has to be sufficiently robust. They can be left plain or printed with an illustration or a patterned design or a block of color. There was once a craze for unusual types of endpaper, such as marbled patterns or recycled papers embedded with flecks of rag or other unbleached materials but, trust me, your printer will not thank you for specifying these and will probably charge extra for the manual work involved in attaching them.

Board covering: There are three ways to go with this: a reconstituted or synthetic leather lookalike, a lightly textured cloth material, or a fully printed paper covering (or PPC). In the past the cloth would have been dyed but it is now more likely to be a basic white material printed with whatever color you desire. Paper for a PPC cover should be around 260 gsm/90# but can be anywhere in the 210 gsm to 270 gsm/80# to 100# range. A leather-like or cloth cover would normally be embossed on the spine with at least the title, author name and publisher’s logo.

Dustjacket: Ideally no less than 128 gsm/90#. And, as with endpapers, the size and format of the book will affect the weight—the heavier the book, the heavier the dustjacket, so anywhere up to 160 gsm/110# would be acceptable. As with the cover, the dustjacket will probably be laminated so the actual thickness will increase anyway.

Printing options

While options are now endless, in broad terms, there are only two methods you to need to know about: offset and digital.

Offset

In the lithographic offset process, whole pages containing text and images are transferred either by photographic means onto thin, flexible printing plates, or ‘burned’ onto the plates by laser directly from a computer file (computer-to-plate or CTP). If necessary, a separate plate is produced for each of the four primary printing colors (CMYK) which, when combined, produce full color images. (See color below)

Each plate is wrapped around a cylinder and inked as it revolves. The plate is then pressed onto a

revolving rubber cylinder which applies the ink to a sheet (sheet-fed) or a large roll (web-offset)

of paper as it travels through the machine. The plates are usually metallic or made from a plasticized material and would wear out quickly if in direct contact with the paper, hence the offsetting.

Digital

This can take many forms but the most common is a hugely scaled-up form of an office laser printer where text paper is fed at high speed through a machine from a large roll. The image is taken from a computer file and applied almost magically by ink or fine powder. The paper is then cut into double-sided pages as it emerges from the end of the machine.

This method is ideal for producing small quantities of books at the outset and then reprints of almost any quantity. Once the text and cover files have been loaded into the machine, there are no further set-up costs, in comparison to platemaking and machine make-ready for the offset process which, generally, have to be completed each time there is a printing. Moreover, it significantly reduces the financial ‘risk’ associated with printing a large quantity of copies prior to publication. Only a small number need to be printed and stock replenished as orders are received. This is commonly referred to as print-on-demand or POD publishing.

Color

In conventional offset printing only sheets that actually contain color images are printed in CMYK, all other pages are printed in black (a ‘monochrome’) as usual. Color illustrations may sometimes be grouped onto a separate set of pages and printed on gloss rather than the normal text stock.

In digital printing it is more than likely that a whole book will be run through a full color machine, irrespective of the number of pages that contain color images or other graphics, or where they might fall in the text.

Choosing a printer

Most medium to large general printers will assure you they can produce books. By this they usually mean they can print the sheets that make up the pages. Whether they are capable of following through with all the remaining ‘finishing’ tasks of folding, collating, trimming, and binding is another matter. Some may well have the necessary equipment but, in reality, most will outsource some or all of these tasks. This may cause problems when it comes to quality assurance and scheduling. Your book is likely to join a long queue where it will be a one-off minnow in a large ocean dominated by big-fish publishers producing, say, thousands of hardback dictionaries or books about football champions. Unless tightly monitored, this has serious implications for scheduling.

Printers overseas, particularly ones in South East Asian countries, rarely have this problem because more often than not they have their own paperback and hardback manufacturing facilities in-house—or at least a good relationship with an associated company.

Indeed, it is worth considering whether you should print overseas. It is not as difficult as you might imagine, especially if you use a reputable broker. They will guide you through the entire process and arrange all aspects of production for you, from checking the computer files to proofing to delivery. Obviously, it will take longer because of extra shipping and customs clearance (up to an additional two months) but there are significant cost advantages.

Brokers

- PrintNinja is a major international print broker which sources its products from companies in China. Although its head office is in the US, it services clients worldwide via a comprehensive website and has production and logistics teams based in Shenzhen.

- KHL is a large printer in Singapore offering a wide range of services, from short-run digital to large format books in full color.

Getting a printer quotation

To get an accurate cost quotation from a printer, you will need to provide some basic details of your project, usually by completing an online enquiry form. Bear in mind that the range of paper types and finished format sizes may be limited if you are planning to print digitally.

- Book title

- Copies: Total quantity required

- Extent: Total number of pages including blanks

- Size: Trimmed page dimensions

- Format: Paperback or hardback? Portrait or landscape?

- Binding: Section-sewn, notch-bound or perfect-bound? (Your printer can recommend what’s best for your book.)

- Paperback cover: Weight and matte or gloss finish?

- Case covering: Cloth or printed paper?

- Printed cover: PPC or dust jacket?

- Color pages: Number of any sections containing full color

- Paper: Type and weight

- Proofs: Digital and/or paper-based

- Advance copies: Number of copies and destination of a few copies for approval before the bulk stock is dispatched

- Delivery: Street address and any issues regarding packing or difficult vehicle access

Certainly, a request for a quote could contain more technical details but, frankly, unless you know exactly what you’re talking about, it would be better for the printer to ask specific questions and advise you accordingly. Nonetheless, they should be able to provide an accurate quote from the above specifications.

Their quote may include a provision for a small percentage of copies that can be supplied over or under the ordered amount. Standard quality control practices mean printers produce more than the required number of printed sheets or finished books to allow for possible spoilage. Sometimes the rejection rate is high and sometimes the opposite can happen and they have more acceptable sheets than anticipated so end up with slightly more books. It simply means they can deliver a different amount (usually between five and 10 percent of the whole run) than ordered and charge you on a pro rata basis.

There may also be a provision in the quote (or the terms and conditions) for increases in the cost of raw materials to be passed on to the customer. It is worth noting, for example, that at the time of writing, global pulp prices have fluctuated significantly over the last six months, however the general trend is upwards.

A printer will want you to accept their quotation as quickly as possible and their sales people may put you under some pressure to do so. For admin reasons they will want to place the project in their future schedules and budgets, so you should make it absolutely clear to them from the start if the quote request and the project itself are speculative and especially if you do not yet have a fixed timetable for production. Once production commences they may require you to pay part or all of the quoted amount upfront.

Note from Jane, especially to Australian readers: If you enjoyed this post, be sure to check out Andrew Watson’s book Cover to Cover.

Andrew,

Thank you for this article. I spent 10 years in print production and now the last 30 years as

an account executive in the printing industry. Much of my time in the last 30 years has been focused on offset and digital book production and working with online POD book printers.

I have worked for largest printer in the U.S. and probably one of the smallest printers in the U. S. and one thing is always the same. When you talk to a printer, try to sound like you have done this before, even if you haven’t.

Your article goes a long way in helping those first timers look and sound knowledgeable.

Like any industry, if you are not carful in how you approach, they may not take you seriously or provide a proposal that meets your needs.

To that end I wanted to respectfully add one term to consider. Where you talk about

“Show-through” I suggest using the term “opacity”. This is the term printers use to describe and measure “show-through” so using this term will add to your image as a savvy prospective customer.

As a budding author myself who has just published my first book, I can’t tell you how many people I have seen go to a printer unprepared to convey the detailed specs and what they actually want. This can lead to small or large negative surprises.

Thank you for writing this article.

Sincerely,

Greg W. Andresen